The inBetPref system is a comprehensive and consistent solution for our customers. It combines cost and time savings with taking responsibility for part of the process: - at the investment preparation stage, providing the selection of solutions and technical advice from the inBet constructor, completed with a construction and workshop design - a "one stop shop" solution, where the customer orders 100% of prefabricated products in one place for the planned investment - responsibility for design, production and logistics is combined in one place, ensuring cohesion.

Designing

Production

Logistics

Loading of shell/double walls

Loading of shell/double walls Shell/double walls assembly

Shell/double walls assembly Filigree slabs assembly

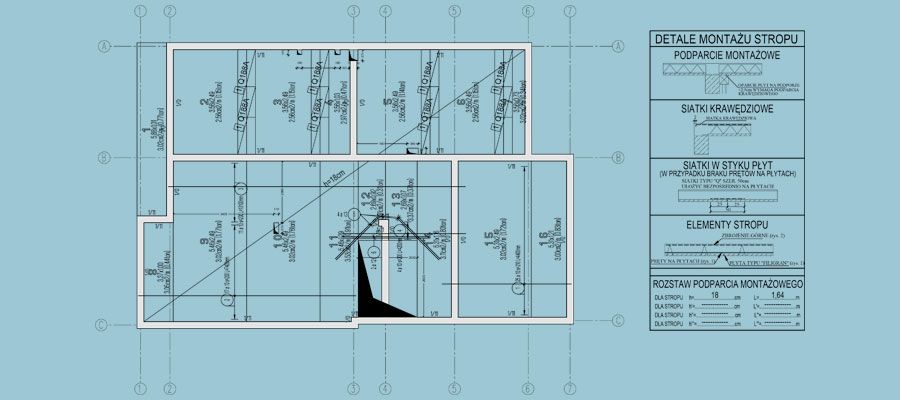

Filigree slabs assembly Installation of supports

Installation of supports Installation of prefabricated flight of stairs

Installation of prefabricated flight of stairs Installation of prefabricated balcony

Installation of prefabricated balcony